The 6.4L Power Stroke was introduced for the 2008 model year to the Ford Super Duty platform. Stricter emissions regulations was the primary factor that presented the need for a new, clean slate engine design. Quieter and cleaner than its predecessors, the 6.4L Power Stroke was the first engine deployed in its segment with a twin turbocharger system as factory equipment. This was also the first Power Stroke to use a diesel particulate filter (DPF) in order to nearly eliminate particulate emissions.

International-Navistar supplied the 6.4L Power Stroke to Ford Motor Company, which is based on the International MaxxForce 7 engine platform. This design moved away from the dated HEUI injection system to a modern high pressure common rail design, the heart of which is a Siemens VDO injection pump. Learning from their experiences with the 6.0L Power Stroke, the 6.4 liter is assembled with larger M16 cylinder head bolts for superior clamping force.

Although the cleanest and most powerful engine supplied to Ford by International, it would also be the last as Ford would begin offering their own design beginning the 2011 model year. The 6.4L Power Stroke's extensive exhaust aftertreatment system was found to severely hinder fuel economy and this new technology was in dire need of refinement. As 6.4's began to rack up miles, the longevity of this engine become seemingly lacking and spacial restraints within the engine bay make these engines somewhat difficult to repair.

6.4 Power Stroke Engine Specs

Engine: |

6.4L Power Stroke, International MaxxForce 7 |

|

Type & Configuration: |

4 stroke diesel, 90° V8 |

|

Applications: |

2008 - 2010 Ford F-250, F-350, F-450, F-550 Super Duty |

|

Advertised Displacement: |

6.4 liters, 390 cubic inches |

|

Calculated Displacement: |

6.36 liters, 388.8 cubic inches |

|

B10 Life: |

Not rated |

|

B50 Life: |

375,000 miles |

|

Bore: |

3.87 inches (98.20 mm) |

|

Stroke: |

4.134 inches (105.00 mm) |

|

Bore/Stroke Ratio: |

0.94 (undersquare) |

|

Compression Ratio: |

17.5:1 |

|

Firing Order: |

1-2-7-3-4-5-6-8 |

|

Cylinder Numbers: |

Cylinders 1, 3, 5, 7 located on the passenger side bank; cylinders 2, 4, 6, 8 located on driver side bank |

|

Engine Block Material: |

Cast iron |

|

Cylinder Head Material: |

Cast iron |

|

Head Bolt Type/Count: |

M16 head bolts, 4 bolts per cylinder |

|

Injection System: |

Direct injection, high pressure common rail with Siemens VDO K16 injection pump (high pressure fuel pump, HPFP), piezo electric fuel injectors |

|

Aspiration: |

Turbocharged & intercooled, air-to-air CAC, BorgWarner V2S twin sequential turbochargers featuring a variable geometry high pressure turbo and fixed geometry low pressure turbo; electric VGT vane position actuator |

|

Valvetrain: |

Conventional overhead valve system (OHV), cam-in-block; gear driven camshaft with 4 valves per cylinder (32 valve) |

|

Cold Start Aid(s): |

Glow plug preheat system, 1 glow plug per cylinder located in combustion chamber |

|

Engine Oil Capacity: |

15.0 U.S. quarts with filter change |

|

Engine Oil Spec: |

SAE 15W-40, SAE 10W-30, SAE 5W-30, SAE 0W-30; see ambient temperature breakdown & API requirements in complete viscosity chart below |

|

Lube Oil Filter P/N: |

||

Fuel: |

Ultra low sulfur diesel fuel (ULSD), B5 biodiesel compatible |

|

Fuel Filter P/N: |

Motorcraft FD-4617 (kit, primary & secondary fuel filters with o-rings) |

|

Peak Horsepower: |

350 hp @ 3,000 rpm |

|

Peak Torque: |

650 lb-ft @ 2,000 rpm |

|

Idle Speed: |

Approximately 650 rpm |

|

Governed Speed: |

Approximately 3,700 rpm |

|

Emissions Equipment: |

Exhaust gas recirculation with dual EGR coolers, diesel oxidation catalyst (DOC), and diesel particulate filter (DPF) with active regeneration integration |

|

Coupled Transmissions: |

Ford 5R110W TorqShift five speed automatic, ZF S6-650 six speed manual transmission |

|

Engine Weight: |

Approximately 1,130 lbs with engine oil |

|

Engine Dimensions: |

Length: |

32 inches |

Width: |

34 inches |

|

Height: |

38 inches |

|

6.4 Power Stroke Engine Oil Viscosity Chart

Engine oil viscosity chart for all 6.4 Power Stroke applications

Ford recommends SAE 15W-40 and 5W-40 engine oils in ambient temperatures greater than 50° F and requires these heavier oils are used in heavy hauling and trailer towing applications. All engine oils used in the 6.4L Power Stroke must meet or exceed API CJ-4/SM specifications. Failure to use these low ash engine oils will result in DPF clogging.

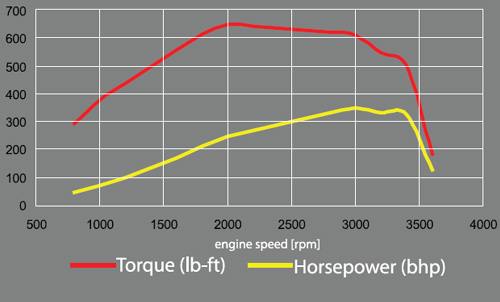

6.4 Power Stroke Horsepower & Torque Curves

6.4L Power Stroke horsepower and torque curves (2008 - 2010 Ford Super Duty)

Like its predecessor, the 6.4L Power Stroke is known for its strong mid-range performance with torque peaking at 2,000 rpm and maintaining reasonably well through 3,000 rpm. Such characteristics are well suited for towing and maintaining speed over long steep grades. The quick spooling twin turbos allow the engine to produce over 500 lb-ft by 1,500 rpm.

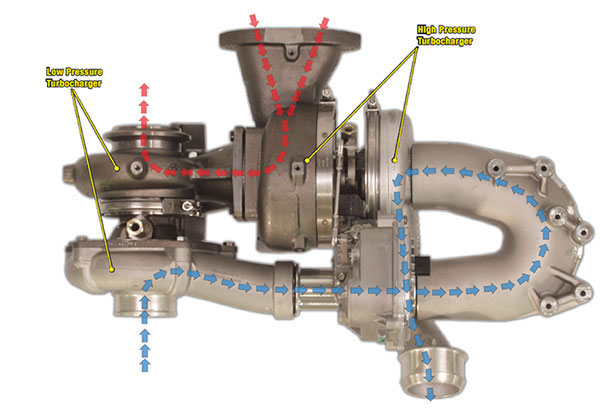

6.4L Power Stroke Twin Turbocharger Operation

Arrangement of the high and low pressure turbochargers on the 6.4L Power Stroke

Image copyright© Ford Motor Company

The twin sequential turbocharger arrangement features a fixed geometry low pressure turbocharger and variable geometry high pressure turbocharger. Exhaust gases enter the turbine of the high pressure turbocharger first and then flow through the low pressure turbocharger. The vane position in the variable geometry turbocharger is controlled by an electric actuator. Fresh air is drawn through the engine air filter and into the compressor of the low pressure turbocharger first, which is then supplied to the high pressure compressor and into the charge-air-cooler.

Common 6.4 Power Stroke Problems

While there are many fairly common issues with the 6.4L Power Stroke, the most proficient complaints include poor fuel economy and engine longevity. This engine's fuel guzzling tendency can be attributed to the diesel particulate filter, which perpetually collects and cyclically incinerates exhaust soot. When the filter reaches a predetermined capacity, a regeneration cycle (active regeneration) is initiated and raw fuel is introduced into the exhaust system where it reacts in the diesel oxidation catalyst to raise the exhaust gas temperature.

The exhaust gases leaving the DOC then reach temperatures high enough to initiate and sustain incineration of particulate matter within the filter. Once the filter has completed its cleaning cycle, the active regeneration mode is terminated and engine operation returns to normal. Poor fuel economy, especially while towing or driving in suburban traffic conditions, is the result of fuel being used during the regeneration cycle. Fuel economy is maximized by traveling at constant speed over long distances on flat terrain.

The active regeneration cycle is also a root cause of the engine's poor longevity. To introduce fuel into the exhaust stream, it is injected late in the exhaust stroke when there is not enough heat to ignite the fuel and exhaust gas mixture. This has a tendency to "wash" the cylinders with fuel, reducing or removing the protective layer of engine oil that minimizes wear between the piston rings and cylinder walls. It also allows fuel to enter the crankcase and dilute the engine oil, attacking the lubricant's viscosity and reducing its effectiveness against preventing wear. This accelerated rate of wear reduces the engine's service life and increases its service requirements.

Summary & Key Points

• The 6.4L Power Stroke is found in 2008 to 2010 model year Ford Super Duty pickup and chassis cab trucks

• This engine platform was designed and manufactured by International-Navistar; it would be the last engine supplied to Ford Motor Company

• A twin sequential turbocharger arrangement, high pressure common rail fuel injection system, and emissions friendly diesel particulate filter are key features of this engine